Professional Sandblasting Services

Expert surface preparation for rust removal, paint stripping, and creating the perfect foundation for any finish. The essential first step in quality metal restoration.

Why Sandblasting?

Sandblasting is the most effective method for preparing metal surfaces. It creates a clean, profiled surface that ensures superior adhesion for subsequent coatings, paints, or plating.

- Complete rust and corrosion removal

- Paint and coating stripping

- Surface profiling for better adhesion

- Removal of mill scale and oxidation

- Preparation for painting or plating

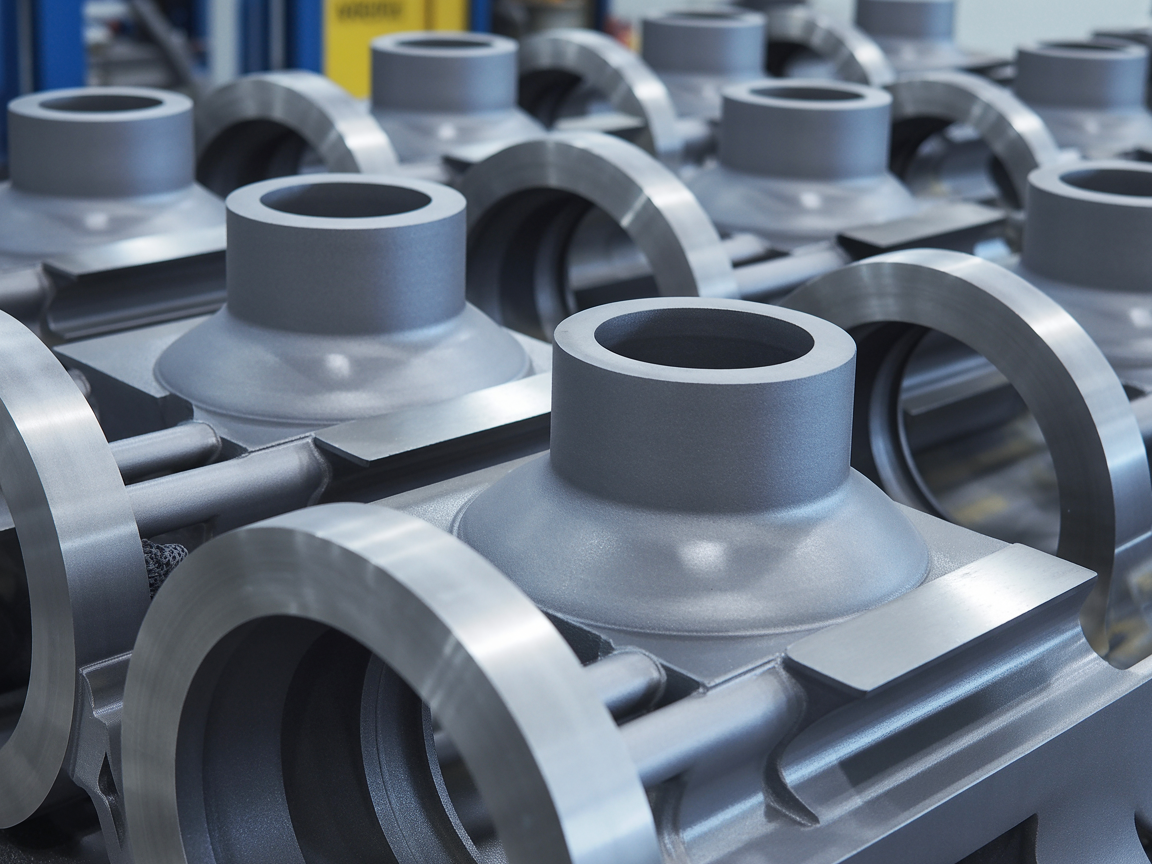

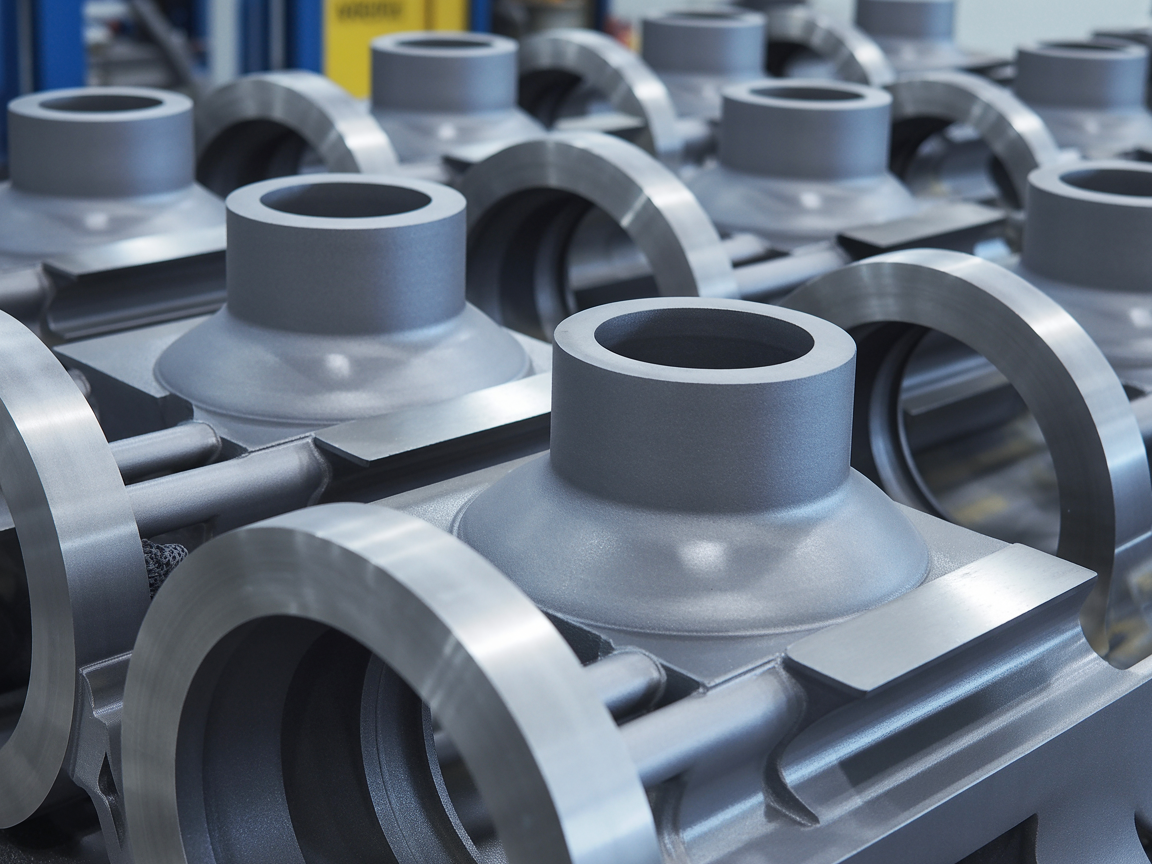

- Cleaning of intricate parts and castings

Our Process

A systematic approach ensuring perfect results every time

Assessment

We evaluate your parts and recommend the optimal media and technique

Preparation

Parts are masked and protected where needed

Blasting

Expert application using appropriate media for your substrate

Inspection

Quality check ensures complete surface preparation

Protection

Immediate protection applied if required before further finishing

Common Applications

Versatile surface preparation for diverse industries

Classic Car Restoration

Bumpers, grilles, engine parts, chassis components

Motorcycle Parts

Frames, engine cases, forks, and trim pieces

Industrial Equipment

Machinery parts, structural steel, tools

Architectural Metalwork

Gates, railings, decorative elements

Fast Turnaround

Most jobs completed within 24-48 hours, rush service available

Quality Guaranteed

Consistent results with SA Class 2.5 surface preparation

Any Size

From small fasteners to large structural components